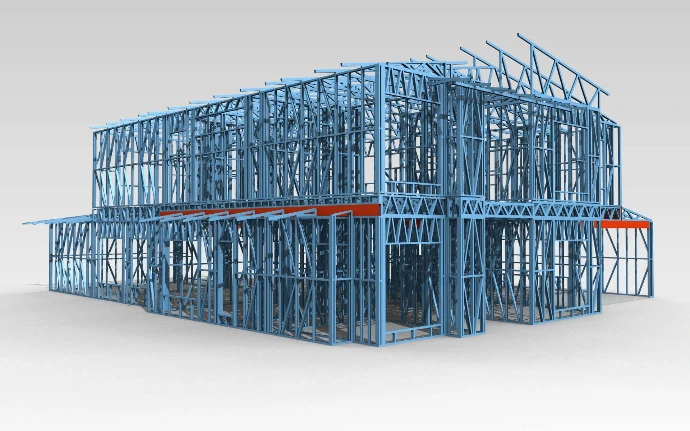

Stronger Structures. Simpler Builds. Smarter Systems.

LoadPath Systems delivers precision-engineered steel framing to accelerate your construction timeline and reduce costs.

Building Today Is Harder Than It Should Be

Traditional wood framing hasn’t kept up with the realities of modern construction. Labor shortages, rising costs, and tighter schedules have turned framing into one of the biggest sources of risk on a project.

- When framing slows down, everything else does too.

- Labor shortages create inconsistent quality and delays.

- Framing errors lead to costly rework downstream.

- Schedules slip as trades wait on corrections.

A Better Way to Build with Steel

LoadPath brings modern principles to framing, replacing guesswork with precision, consistency, and control.

- Construction, Reimagined as a System

- Reduces labor with engineered components.

- Minimizes waste and cost overruns.

A Clear Path from Design to Installation

Adopting a better way to build shouldn’t mean adding complexity. That’s why LoadPath uses a simple, proven process that guides your project from concept to installation with clarity and control. Each step is designed to remove uncertainty, reduce risk, and keep your build moving forward — without disrupting how your team works.

Design & Engineering

Every project begins with a fully engineered design that aligns architectural intent with structural performance.

Using advanced modeling tools, our team creates accurate, code-compliant plans.

You get a clear, buildable path forward — from the very beginning.

We start with clarity.

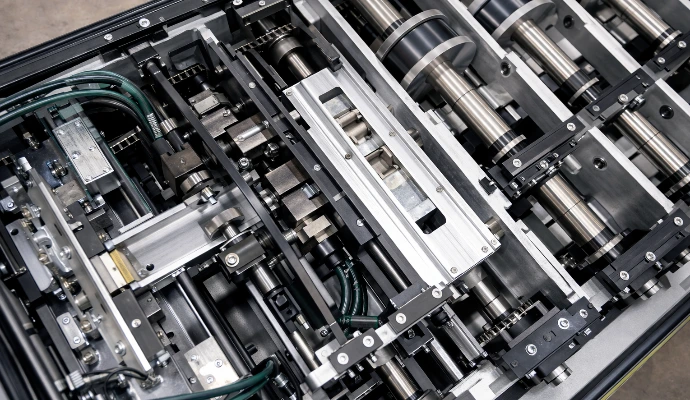

Precision Roll-Forming

We turn designs into exact components.

Steel is shaped with tight tolerances to ensure every component matches the engineered intent.

The result: consistent parts, reliable fit, and fewer surprises in the field.

Prefabrication & Quality

We control quality before it reaches the jobsite.

Panels are assembled in a controlled environment and inspected for accuracy, alignment, and structural integrity.

This process removes variability, reduces waste, and ensures every panel is ready to perform as designed.

Quality is built in — not inspected in later.

On-Site Installation

We make installation faster and more predictable.

Panels arrive ready to install, allowing crews to work efficiently with minimal adjustments.

Engineered connections ensure alignment, speed, and consistency from start to finish.

The result: faster schedules, cleaner builds, and greater confidence on site.

Smarter Systems. Built Right. Proven in the Field.

See how panelized steel framing is assembled on site. Real construction speed, real precision, no sales pitch.

A Superior Way to Build

From groundbreaking to move-in, LoadPath Systems offers tangible benefits for developers, builders, and homeowners alike.

Build Up to 50% Faster

Our panelized systems are assembled on-site in days, not weeks, dramatically accelerating your project timeline and reducing carrying costs.

Cost Certainty

Lock in your framing costs upfront. With off-site fabrication, you avoid the risks of on-site labor shortages and material price volatility.

Unmatched Precision

Every component is digitally designed and machine-fabricated for perfect-fit assembly. This means straighter walls, level floors, and a higher quality structure.

Sustainable & Strong

Built with recycled steel, our systems are lightweight, non-combustible, and resistant to mold and pests, with minimal on-site waste.

Built for Builders Who Value Predictability

From high-expectation homes to multifamily and commercial projects, we support teams that rely on planning, coordination, and consistent structural performance.

Semi-Custom & Custom Residential

Builders delivering high-quality homes where precision, schedule control, and consistent execution matter as much as design.

Multifamily

Developers and builders managing scale, repetition, and tight timelines where structural consistency and sequencing impact returns.

Commercial

Projects that demand structural reliability, coordinated execution, and predictable outcomes across mixed-use and light commercial.

Start with Clarity, Not Commitment

Share a few details about your company and upcoming project. We’ll provide a pre-engineering budgetary estimate to help you evaluate fit and next steps.

Frequently Asked Questions

Have questions? We have answers. Here are some common inquiries about our process and systems.